1, Loading partTo Avoid the low-e Glass put inverse side and Leave wheel marks or scratch low-e Coating We use coating inspection -metal film conductive (other company use Photoelectric detection, hard to recognize for higher transparent film coating)(Nylon and Polyurethane + metal column)2, Washing and Drying part* 3 pairs of soft brush can clean low-e glass and ordinary glass, soft hair diameter less than 0.1mm.* Stainless steel, rust proof.* The air knife is float design, and the appropriate distance between the glass surface and the air knife is always 3mm (Note :3mm is the best

Contate agora

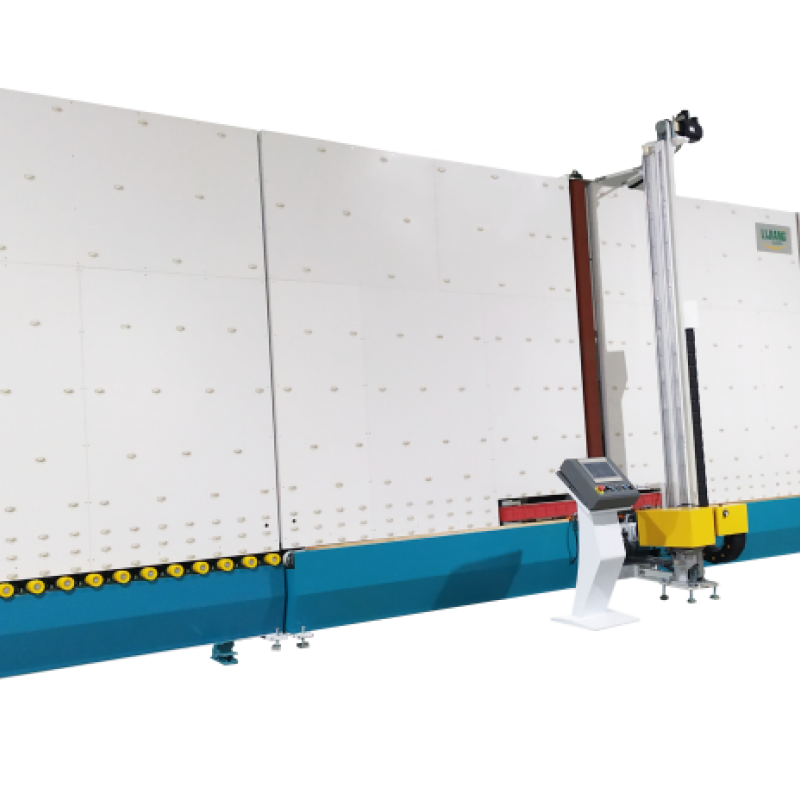

LJBZ2535 Automatic Vertical Insulating Glass Production LineThe whole LJBZ2535 Insulating Glass Production Line has 7 sections: 01 transfer section; 02 washing machine; 03 discharge section;04 inspection and installation section; 05 transfer section;06 pressing and filling section; 07 discharge section.

Contate agora

Insulating glass production line for Glass processingTransmission partAutomatic insulating glass production line adopts coating detection (other companies adopt photoelectric detection, and it is difficult to identify the coating with high transparency)2.

Contate agora

Main featureClean working, easy and flexibleIt is used for fixing and rotating glass at the same time as manual coating the out of doors of ig glassThe center sucker is appropriate for small portions of glass,but,more manual frame is for huge quantities of glassTechnical dataPower supply380V 50HzTotal power0.37kwOperating dimension1500*1500mmDimension600*550*985mmWeight75/48kg

Contate agora

Vertical Insulating Glass Production line is used for making insulating glass for buildings, domestic home windows and doors, moreover for ship, refrigerator, freezer and so on. This IG line includes glass washing and glass pressing machine, it is able to make double / triple glazing glass, for aspects step glass.

Contate agora

Vertical Insulating Glass Production line is used for making insulating glass for buildings, windows and doors, also for ship, refrigerator, freezer and so on. This IG line contains glass washing and glass pressing machine, it can make double / triple glazing glass, for sides step glass.

Contate agora

Vertical automatic insulating glass production line is mainly used for the production of building insulating glass, household doors and Windows insulating glass, ship insulating glass, refrigerator insulating glass, freezer insulating glass, etc. The production line is composed of glass cleaning machine and glass expediting machine, which can produce double/triple layers of glass for cutting step glass.

Contate agora

1. UsageLJBZ2500PG Vertical insulating glass production line has the following functions: Washing glass, Installing aluminum frame, Pressing normal IG units, Pressing double IG units, Pressing double three-layers IG units. LJBZ2500PG is a special equipment in the production of insulating glass with aluminum strip, which has so many advantages, such as small footprint, high efficiency, reliable performance, convenient maintenance and so on.

Contate agora

Vertical insulating glass manufacturing line is used for making insulating glass for homes, domestic domestic home windows and doors, furthermore for deliver, fridge, freezer and so forth. this ig line consists of glass washing and glass pressing system, it may make double / triple glazing glass, for sides step glass.

Contate agora

Vertical Insulating Glass Production line is used for making insulating glass for buildings, windows and doors, also for ship, refrigerator, freezer and so on. This IG line contains glass washing and glass pressing machine, it can make double / triple glazing glass, for sides step glass. The optional function of filling argon gas is available, the air content is more than 90% at least.Technical data Max. glass size 2500mm*3500mm Min.

Contate agora

Vertical insulating glass manufacturing line is used for making insulating glass for homes, home home windows and doors, moreover for deliver, fridge, freezer and so forth. this ig line includes glass washing and glass urgent system, it is able to make double / triple glazing glass, for facets step glass.

Contate agora

LJBZ2535G Automatic Vertical Insulating Glass Inflatable Inside and Outside Plate Production Line Adopt SIEMENS Control SystemProduct DescriptionLJBZ2535 Automatic Insulating Glass Production LineThe whole LJBZ2535 Insulating Glass Production Line has 7 sections: 01 transfer section;

02 washing machine;

03 discharge section;

04 inspection and installation section;

05 transfer section;

06 pressing and filling section;

07 discharge section.Optional functions: •Step glass with optional edges

•Shaped glass

•Filling argon gas automatically

•Air-floating technology to tr

Contate agora

APPLICATIONAutomatic molecular sieve filling machine can automatically complete the drilling action, filling molecular sieve and seal a series of actions in the interval frame. Molecular sieve filling machine manipulator using Germany Siemens, filling speed, strong operation, to ensure the effective closing performance of sealant. Molecular sieve filling machine is a high-end equipment to improve the quality of insulating glass, and is an essential equipment in insulating glass production equipment.1.All spare parts have ID Number for offering the convenience in after sales service.2.

Contate agora

ApplicationLJDM2545 smart vertical edge deleting machine is used to delete the edge film of the Low-e glass. The glass edge deleting machine adopts imported servo control system, positioning accurately with smooth operation. High quality grinding wheels are durable, can produce neat and beautiful grinding crack.

Contate agora

1. Vertical Edge Deleting Machine UsageVertical Edge Deleting Machine LJCM2545 is used to remove low-e film from edges of the glass. It can be connected to the insulating glass production line and is necessary equipment in insulated glass processing. Speed of transmission and grinding are adjustable, and the machine is equipped with automatic cleaning system.

Contate agora

LJTB01 Butty Extruder Machine ApplicationSealant extrusion coating machine is used for spreading aluminum spacer frames evenly with hot melt butyl.Spreading Butyl Extruder Machine use large electrical control panel which makes the operation more easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min, which has the fastest speed in China. Hydraulic hot melt butyl machine is very popular with energy-saving.

Contate agora

PERFORMANCEThe coating glue velocity can attain forty seven m/ minSaving glue via way of means of as compared with normal machine.

Contate agora

Silicone extruder machine Two-component Sealant-Spreading Machine LJST02Ainsulating glass sealantsmall extruder machinesealant dispensing equipmentsealant dispensing machinesilicone extruder machineTwo-component Sealant-Spreading Machine was designed by advanced technology from abroad and inside of China.Two-component Sealant-Spreading Machine is special equipment used for spreading the two-component polysulphide glue and/or two-component silicone structureglue for the aluminum type insulating glass or curtain wall glass.A and B pump in the Two-component Sealant-Spreading Machine adopt Ko

Contate agora

Lijiang butyl extruder machine is used to apply hot melt butyl to the aluminum spacers of insulating glass evenly. The use of large electrical control panel makes the operation easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min. The squeezing system adopts pneumatic and hydraulic supercharging system, which makes the squeezing pressure more stable. The machine is energy-saving. The dispensing cylinder uses rotate supporting system and this makes the refill of butyl easier.

Contate agora

PERFORMANCEGermany Siemens PLC control system,stable performanceAutomatically drilling, filling and sealingThe machine height can be adjusted according to the size of spacer frameAutomatically loading and replenish molecular sieveAdvanced feeding device designed according to the principle of gas flowAdopt Industrial plastic spraying treatment of all racksCore parts adopts famous imported brandADVANTAGE

Contate agora

Main featureIt is used for polishing single glass, to prevent to hurt workman from sharp glass edgeIt adopts type of ‘x’ to polish the up and down edge at the same timeEasy operating, simple and flexible Technical dataPower supply380V 50HzTotal power3kwDimension2000*1200*820mm

Contate agora

ApplicationThe two-component gluing machine is designed by advanced technology at home and abroad. It is a special equipment for applying two-component polysulfide adhesive and/or two-component silicone structural adhesive to insulating glass or curtain wall glass. A, B pump using Korean HASCO brand, so as to ensure reliable working effect.Special mixing device of two-component gluing machine ensures high quality mixing of two-component polysulfide glue and/or two-component silicone structural glue.

Contate agora

Four pieces igu may be gas stuffed on the same time inside 20s (1m*1m glass).Pressure alarm tool:while the fuel filling is up to adjusted cost,it will alarm and prevent mechanically.The filling system can show at the contact display screen.Gas content setting: the customer can set the argon content in the igus according to his very own wishes.The whole filling method and argon gasoline content can be displayed at the screen, and the argon gasoline content may be found in real time.Main technical parameterPower supply220V 50HzTotal power0.2kwDimension650*450*1270mmDetails

Contate agora

LJTB01 butyl extruder machineThe type of LJTB01 butyl extruder machine is used for spreading aluminum spacer frames evenly with hot melt butyl. LJTB01 butyl extruder machine use large electrical control panel which makes the operation more easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min, which has the fastest speed in China. LJTB01 butyl extruder machine is very popular with energy-saving. Its squeezing system adopts pneumatic and hydraulic supercharging system, which makes the squeezing pressure more stable.

Contate agora