PERFORMANCESix sets of servo motors, British TRIO systemInlet-outlet with two-direction , 4 directions are availableAutomatically measure glass sizeAutomatically distinguish Low-E filmThe width of edge deletion is adjustablePLC control system, touch screen interfaceIntelligent control system, can recognize batch processing Deleting shaped glass Recognize Low-E fil

Contate agora

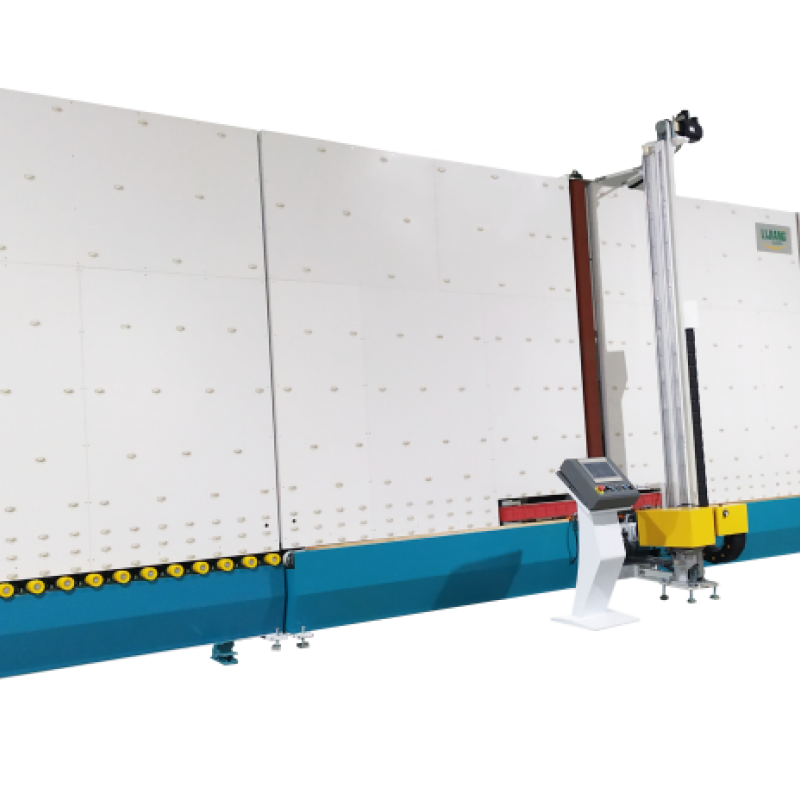

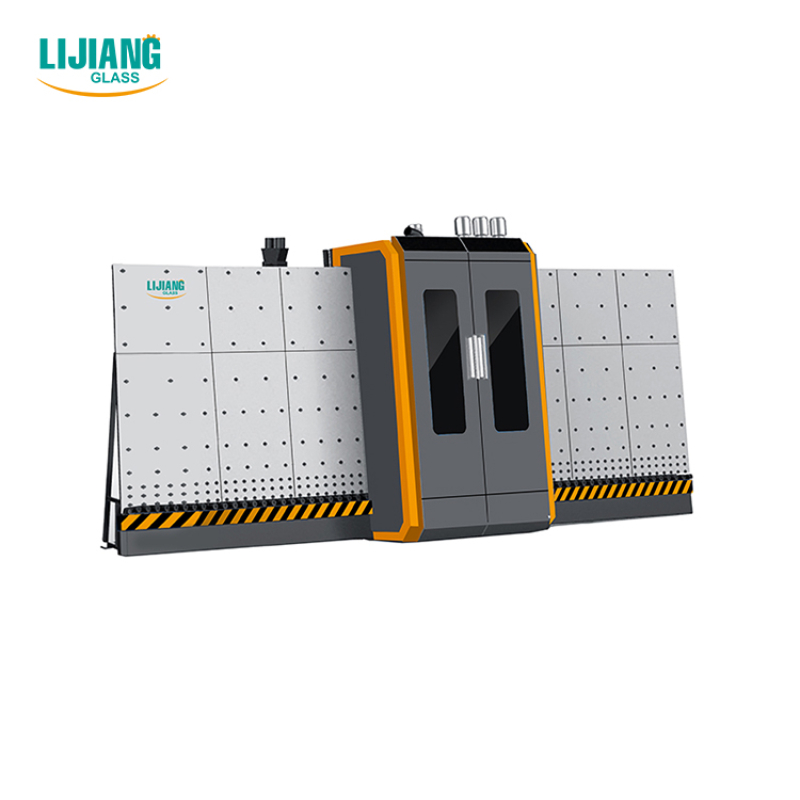

1. Vertical Edge Deleting Machine UsageVertical Edge Deleting Machine LJCM2545 is used to remove low-e film from edges of the glass. It can be connected to the insulating glass production line and is necessary equipment in insulated glass processing. Speed of transmission and grinding are adjustable, and the machine is equipped with automatic cleaning system.

Contate agora

PERFORMANCESix units of servo motors, British TRIO systemInlet-outlet with two-direction , four instructions are availableAutomatically degree glass sizeAutomatically distinguish Low-E filmThe width of part deletion is adjustablePLC manage system, contact display screen interfaceIntelligent manage system, can apprehend batch processing Deleting shaped glass Recogn

Contate agora

ApplicationLJDM2545 smart vertical edge deleting machine is used to delete the edge film of the Low-e glass. The glass edge deleting machine adopts imported servo control system, positioning accurately with smooth operation. High quality grinding wheels are durable, can produce neat and beautiful grinding crack.

Contate agora

ApplicationLJDM2545 clever vertical facet deleting gadget is used to delete the brink movie of the Low-e glass. The glass facet deleting gadget adopts imported servo manage system, positioning appropriately with easy operation. High high-satisfactory grinding wheels are durable, can produce neat and delightful grinding crack.

Contate agora

Smart Vertical Edge Deleting Machine LJCM2545 Main feature• Two-way glass access• Delete double and triple silver low-e glass• Automatically measure glass size• Automatically distinguish low-e surface• Edge deletion is adjustable• The head can be rotated 360°• Safe and full automatic device• PLC control system, touch screen interface • Six servos control system• Intelligent control system, can recognize batch processing Technical dataMax. glass processing size2500*4500mm Min. glass pr

Contate agora

1, Loading partTo Avoid the low-e Glass put inverse side and Leave wheel marks or scratch low-e Coating We use coating inspection -metal film conductive (other company use Photoelectric detection, hard to recognize for higher transparent film coating)(Nylon and Polyurethane + metal column)2, Washing and Drying part* 3 pairs of soft brush can clean low-e glass and ordinary glass, soft hair diameter less than 0.1mm.* Stainless steel, rust proof.* The air knife is float design, and the appropriate distance between the glass surface and the air knife is always 3mm (Note :3mm is the best

Contate agora

LJTJ2025 Automatic Insulating Glass Coated Glass Double Component Sealing Robot MachineProduct DescriptionLJDM2545 Smart Vertical Edge Deleting MachineLJDM2545

smart vertical edge deleting machine is used to delete the edge film of

the Low-e glass. The glass edge deleting machine adopts an imported servo

control system, positioning accurately with smooth operation. High-quality grinding wheels are durable and can produce neat and beautiful

grinding cracks.

Contate agora

Insulating Glass sealing robotTransfer sectionCoating detection mechanism, automatic detection of offline Low-e film Washing machine1. Using 6 pieces of soft brushes with 0.lmm soft hair. can wash low- glass2. New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak.

Contate agora

KTLQ-2500 Vertical Glass Washing MachineKTLQ-2500 glass washing machine can wash maax glass of 2500mm*3500mm, more large size and less size can be optional. - Self-Diagnosis system with touch screen on computer. - Stainless steel washer with 8 ( 6 ) brushes, soft brushes from MONFORTS of Germany, hard brushes automatically open when Low-E glass input. - Rotate speed of brush frequency control. (optional) - Stainless steel air knife is automatically adjustable according to glass thickness, Max thickness to 19mm.

Contate agora

Insulating glass production Line About the IG line only need focus on the two part -WASHING DRYING PART AND PRESSING PART .All other part just conveyors and assembly, no much technology, so please focus on that two . A, washing and drying part1, To Avoide the low-e Glass put inverse side and Leave wheel marks or scratch low-e Coating We use coating inspection -metal film conductive (other company use Photoelectric detection, hard to recognize for higher transparent)(Nylon and Polyurethane + metal

Contate agora

AUTOMATIC GLASS WASHING AND COMBINING LINE WITH HYDRAULIC PANEL PRESS 3300*7000 mmAutomatic glass washing and combining line with hydraulic panel press can assemble and press double, triple or structural (step, facade) insulating glass units.Model of Standard line: LJZB3370PERFORMANCE:1.The whole line use Germany Siemens PLC control system,touch screen interface,Easy and convenient operation .2.In the first section you can see the sensor , It can detect the film of Low-e glass.(At the same time, it can also automatically measure the thickness of the glass )15-30 mm.3.3 pairs of soft brushes ca

Contate agora

Main featureIt is used for storing the gun when manual glue gun stop work during the process of gluing insulating glassStoring at low temperature,to prevent sealant solidifyApply to polysulfide and siliconeCan be effectively reduced waste when cleaning the glueTechnical dataMax refrigerating temperature70ºCMin heating temperature-40ºCTotal power3.8kwRefrigerating<150minOverall dimension1550*60*1300mm

Contate agora

LJBZ2025 Automatic Vertical Laminated Insulating Glass Double Glazing Production Line Details DisplayThe whole insulating glass production line usually includes 7 parts: (from right to left)1, The Loading section(with Low-E checking) 2, The washing and drying section(can wash Low-E glass) 3, The conveyor section 4, The checking and assembly section 5, The conveyor measure, and the sensor section 6, The press part with gas filling 7, The unloading section.The second part: is the washing and drying section.In this glass cleaning section, there are thre

Contate agora

PERFORMANCE of Vertical Insulating air-floating Glass Processing LineAir floating back plate , to avoid the wheel scraching the glass and leaving wheel marksTwo pieces of IGU could be pressed and filled gas in once time, high work efficiency Gas filling in pressing,automatic filling the glass in different areas according to the size of glassGermany Siemens PLC control system, touch screen interface Automatic identification of coated and Low-E glass3 pairs of soft brushes can wash online and offline Low-E glass The washing machine adopts SS material and waterproof deviceWater tan

Contate agora

Main featureIt is used for storing the gun while guide glue gun prevent paintings throughout the technique of gluing insulating glassStoring at low temperature,to save you sealant solidifyApply to polysulfide and siliconeCan be efficiently decreased waste while cleansing the glueTechnical dataMax refrigerating temperature70ºCMin heating temperature-40ºCTotal power3.8kwRefrigerating<150minOverall dimension1550*60*1300mm

Contate agora

PERFORMANCEThe coating glue velocity can attain forty seven m/ minSaving glue via way of means of as compared with normal machine.

Contate agora

APPLICATIONAutomatic molecular sieve filling machine can automatically complete the drilling action, filling molecular sieve and seal a series of actions in the interval frame. Molecular sieve filling machine manipulator using Germany Siemens, filling speed, strong operation, to ensure the effective closing performance of sealant. Molecular sieve filling machine is a high-end equipment to improve the quality of insulating glass, and is an essential equipment in insulating glass production equipment.1.All spare parts have ID Number for offering the convenience in after sales service.2.

Contate agora

LJTB01 Butty Extruder Machine ApplicationSealant extrusion coating machine is used for spreading aluminum spacer frames evenly with hot melt butyl.Spreading Butyl Extruder Machine use large electrical control panel which makes the operation more easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min, which has the fastest speed in China. Hydraulic hot melt butyl machine is very popular with energy-saving.

Contate agora

Insulated Double Glazed Glass Production Line seriesSizes :2000*2500mm2500* 3500mm3300* 7000mmFunctions :double glazing glasstriple glazing glassfour sides step glazing glassSpecial technology of IG Line :Making two pieces of IG units in once timeFilling argon gas onlineShaped glazing glassLow-e film glazing glassAir floating insulating glass lineMain Features of IG Line:• Adopt SIEMENS control system, keep stable performance• PLC control system, touch screen interface• Applicable to produce stepped IG, triple IG and shaped IG• Using servo to control system, modular function, superposition fun

Contate agora

PERFORMANCEThe coating glue speed can reach 47 m/ minSaving glue by compared with ordinary machine.

Contate agora

Silicone extruder machine Two-component Sealant-Spreading Machine LJST02Ainsulating glass sealantsmall extruder machinesealant dispensing equipmentsealant dispensing machinesilicone extruder machineTwo-component Sealant-Spreading Machine was designed by advanced technology from abroad and inside of China.Two-component Sealant-Spreading Machine is special equipment used for spreading the two-component polysulphide glue and/or two-component silicone structureglue for the aluminum type insulating glass or curtain wall glass.A and B pump in the Two-component Sealant-Spreading Machine adopt Ko

Contate agora

Lijiang butyl extruder machine is used to apply hot melt butyl to the aluminum spacers of insulating glass evenly. The use of large electrical control panel makes the operation easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min. The squeezing system adopts pneumatic and hydraulic supercharging system, which makes the squeezing pressure more stable. The machine is energy-saving. The dispensing cylinder uses rotate supporting system and this makes the refill of butyl easier.

Contate agora

Automatic Glass Washing MachineGeneral description of Automatic Glass Washing MachineAutomatic Glass Washing Machine consists of in-feed, prewash, washing&drying, out-feed section. To make good washing performance and quick air dry, it adopts 3 pairs brushes and 2 pairs air knives with 1pc air blower. It fits for tempered glass, solar glass, laminated glass, Low-e glass or any other flat glass processing. Parameter of Glass Washing MachineParameterMax. Width: 2000mmMin.

Contate agora