Description of Glass Sandblasting MachineGlass automatic sandblasting machine control by the PLC, suitable for processing 5-40mm thickness of flat glass to different kind of frosting patterns . The transmission control by the photo switch and limit switch automatically. Glass conveys by the belt, and the guns driven by chain so that can be move up and down for sandblasting (the distance can be adjusted according to the requirement). Stable transmission, high efficiency and easy maintenance of the chain system.

Contate agora

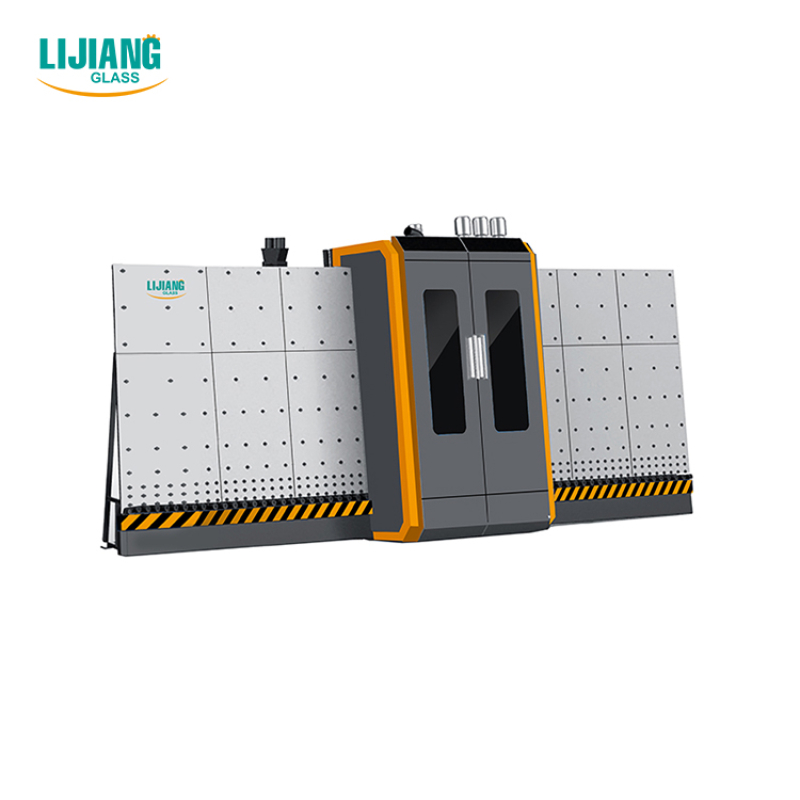

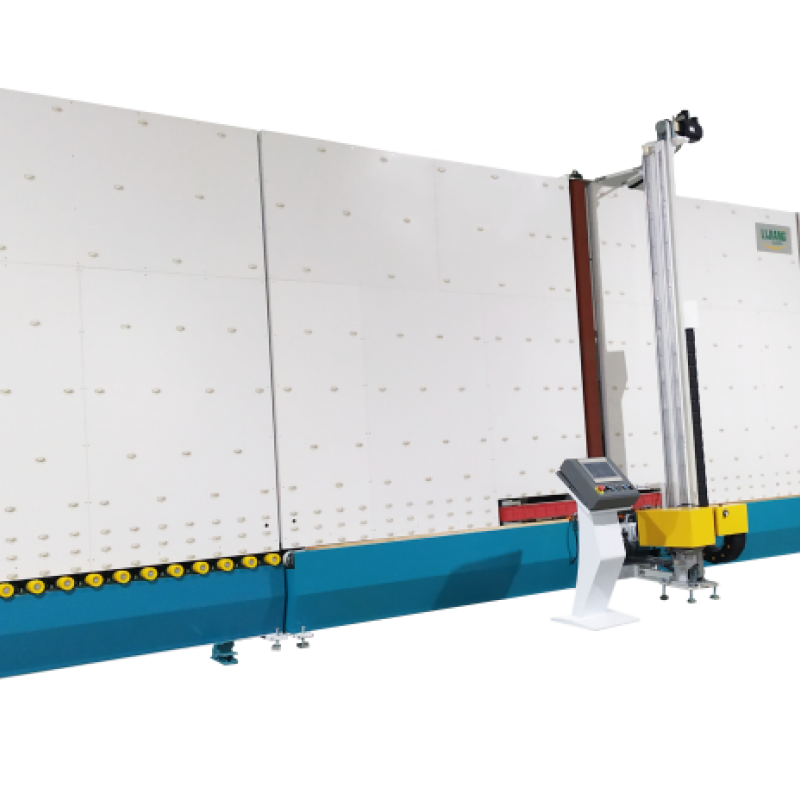

ApplicationLJDM2545 smart vertical edge deleting machine is used to delete the edge film of the Low-e glass. The glass edge deleting machine adopts imported servo control system, positioning accurately with smooth operation. High quality grinding wheels are durable, can produce neat and beautiful grinding crack.

Contate agora

Automatic desiccant filling machine for glass processingDetail introductionThe automatic desiccant filling machine can automatically punch holes, fill desiccant and seal the insulating glass spacer frame. Automatic desiccant filling machine using Germany Siemens control system, filling speed, stable operation, to ensure the effective closing performance of sealant.

Contate agora

LJTB01 butyl extruder machineThe type of LJTB01 butyl extruder machine is used for spreading aluminum spacer frames evenly with hot melt butyl. LJTB01 butyl extruder machine use large electrical control panel which makes the operation more easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min, which has the fastest speed in China. LJTB01 butyl extruder machine is very popular with energy-saving. Its squeezing system adopts pneumatic and hydraulic supercharging system, which makes the squeezing pressure more stable.

Contate agora

Silicone extruder machine Two-component Sealant-Spreading Machine LJST02Ainsulating glass sealantsmall extruder machinesealant dispensing equipmentsealant dispensing machinesilicone extruder machineTwo-component Sealant-Spreading Machine was designed by advanced technology from abroad and inside of China.Two-component Sealant-Spreading Machine is special equipment used for spreading the two-component polysulphide glue and/or two-component silicone structureglue for the aluminum type insulating glass or curtain wall glass.A and B pump in the Two-component Sealant-Spreading Machine adopt Ko

Contate agora

APPLICATIONAutomatic molecular sieve filling machine can automatically complete the drilling action, filling molecular sieve and seal a series of actions in the interval frame. Molecular sieve filling machine manipulator using Germany Siemens, filling speed, strong operation, to ensure the effective closing performance of sealant. Molecular sieve filling machine is a high-end equipment to improve the quality of insulating glass, and is an essential equipment in insulating glass production equipment.1.All spare parts have ID Number for offering the convenience in after sales service.2.

Contate agora

A cnc reducing system’s maximum obvious characteristic is that it cuts via direct physical contact.

Contate agora

Lijiang butyl extruder machine is used to apply hot melt butyl to the aluminum spacers of insulating glass evenly. The use of large electrical control panel makes the operation easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min. The squeezing system adopts pneumatic and hydraulic supercharging system, which makes the squeezing pressure more stable. The machine is energy-saving. The dispensing cylinder uses rotate supporting system and this makes the refill of butyl easier.

Contate agora

LJTJ2025 Automatic Insulating Glass Coated Glass Double Component Sealing Robot MachineProduct DescriptionLJDM2545 Smart Vertical Edge Deleting MachineLJDM2545

smart vertical edge deleting machine is used to delete the edge film of

the Low-e glass. The glass edge deleting machine adopts an imported servo

control system, positioning accurately with smooth operation. High-quality grinding wheels are durable and can produce neat and beautiful

grinding cracks.

Contate agora

Smart Vertical Edge Deleting Machine LJCM2545 Main feature• Two-way glass access• Delete double and triple silver low-e glass• Automatically measure glass size• Automatically distinguish low-e surface• Edge deletion is adjustable• The head can be rotated 360°• Safe and full automatic device• PLC control system, touch screen interface • Six servos control system• Intelligent control system, can recognize batch processing Technical dataMax. glass processing size2500*4500mm Min. glass pr

Contate agora

KTLQ-2500 Vertical Glass Washing MachineKTLQ-2500 glass washing machine can wash maax glass of 2500mm*3500mm, more large size and less size can be optional. - Self-Diagnosis system with touch screen on computer. - Stainless steel washer with 8 ( 6 ) brushes, soft brushes from MONFORTS of Germany, hard brushes automatically open when Low-E glass input. - Rotate speed of brush frequency control. (optional) - Stainless steel air knife is automatically adjustable according to glass thickness, Max thickness to 19mm.

Contate agora

PERFORMANCEThe coating glue speed can reach 47 m/ minSaving glue by compared with ordinary machine.

Contate agora

1. What is the role of aluminum strip bending machine? Why do aluminum bars bend?Aluminum strip bending machine is mainly used for continuous bending of insulating glass aluminum strip. Aluminum strip bending can improve the sealing performance of insulating glass and its appearance is better2. What kinds of rigid insulating glass spacer are there?

Contate agora

Professional Customized Auto Insulating Glass Aluminum Spacer Strip Bar Bending Machine Could Foldable Special Shape BendingProduct DescriptionLJZW2020 Automatic Aluminum Spacer Bar Bending MachineJinan LIJIANG Glass Automatic Insulating Glass Spacer Bar Bending Machine is the special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication techniques.

Contate agora

High-Efficiency LJTJ2025 Automatic Sealing Robot 2.5m Vertical Insulating Glass Laminating Machine Could be ConnectedProducts DescriptionAutomatic Vertical Insulating Glass Sealing RobotAutomatic insulating glass sealing robot can be connected to 2.5m vertical insulating glass glue machineProduct descriptionThe automatic vertical insulating glass sealing robot evenly smears the mixed sealant on the outer channel of the insulating glass through the servo mechanism, which is helpful to improve the sealing and bonding performance of the insulating glass.Advantages & FeaturesBenefits & Adv

Contate agora

Automatic Horizontal Insulating Glass Aluminum Strip Bar Bending Machine with Touch Screen Interface and Four Storage TroughsProduct DescriptionLJZW2020 Automatic Aluminum Spacer Bar Bending MachineJinan LIJIANG Glass Automatic Insulating Glass Spacer Bar Bending Machine is a special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication technology.

Contate agora

Main featureClean working, easy and flexibleIt is used for fixing and rotating glass at the same time as manual coating the out of doors of ig glassThe center sucker is appropriate for small portions of glass,but,more manual frame is for huge quantities of glassTechnical dataPower supply380V 50HzTotal power0.37kwOperating dimension1500*1500mmDimension600*550*985mmWeight75/48kg

Contate agora

PERFORMANCEJapan yaskawa servo manipulate machine, whole computerized and high-efficiencyComputerized reminiscence function, no need to enter parameters time and againAutomatically restore glass corners with scraper and curlerGadget has 4 sections, can maintain glassRobotically diploma glass duration and glue depth, adjust sealing velocityAdopt timing belt, smooth transfer and accurate roleEvery vehicle-feature is with manual operationCan coat double glass, fashioned glass, step glass, triple glassOne set of booster pump controls organizations of sealantsAutomatic timing glue discharging

Contate agora

1. Vertical Edge Deleting Machine UsageVertical Edge Deleting Machine LJCM2545 is used to remove low-e film from edges of the glass. It can be connected to the insulating glass production line and is necessary equipment in insulated glass processing. Speed of transmission and grinding are adjustable, and the machine is equipped with automatic cleaning system.

Contate agora

Specification of Insulating glass sealing robotModelLJTJ2540DVoltage Power380V 13KWAir Pressure0.5~0.7MpaExtruding pressure32MpaMax.Glass size2500*4000mmMin.Glass size400*300mmGlass thickness12~56mmWorking speed5~40m/minOverall dimension11000*1500*4500mmFunction and feature of Insulating glass sealing machine1.Insulating glass sealing machine is suitable for glass deep processing enterprise ,high automation, Reduce labor intensity, save manpower, improve production efficiency 2. Whole machine adopt man-machine touch screen interface,with memory function .

Contate agora

Hot Melt Adhesive Insulating Glass Production Line Beam Tape Coating Equipment Butyl Extruder Tape Coating MachineProduct DescriptionJinan LIJIANG Glass LJTB01 Butyl Extruder MachineThe type of LJTB01 butyl extruder machine is used for spreading aluminum spacer frames evenly with hot melt butyl. LJTB01 butyl extruder machine use large electrical control panel which makes the operation more easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min, which has the fastest speed in China.

Contate agora

PERFORMANCESix sets of servo motors, British TRIO systemInlet-outlet with two-direction , 4 directions are availableAutomatically measure glass sizeAutomatically distinguish Low-E filmThe width of edge deletion is adjustablePLC control system, touch screen interfaceIntelligent control system, can recognize batch processing Deleting shaped glass Recognize Low-E fil

Contate agora

Overview of Glass Cutting MachineAdvantages of glass sandblasting machine1) Fast movement, stable action, high precision controller.2) The HMI is simple and elegant, easy to adjust the parameters.3)Photoelectric positioning cutting mode, direct cutting mode, oil-free cutting mode, automatic/empty mode can be switched at any time during the processing.4) Graphics library nesting programming, select the special shape from the library, set the relevant parameters and the quantity, it can be directly nested and cut.5)The compl

Contate agora

Jinan LIJIANG Glass LJTB01 Butyl Extruder MachineThe type of LJTB01 butyl extruder machine is used for spreading aluminum spacer frames evenly with hot melt butyl. LJTB01 butyl extruder machine use large electrical control panel which makes the operation more easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min, which has the fastest speed in China. LJTB01 butyl extruder machine is very popular with energy-saving.

Contate agora