Production Description of the product: The product can load of 600 kg. It is able to be used with out outside electricity deliver. the suction, release and rotation of the suction cup are all managed by remote control. each suction cup has a separate switch which may be used as required, and the suction cup holder has a telescopic rod which can be hooked up or removed as required.

Contate agora

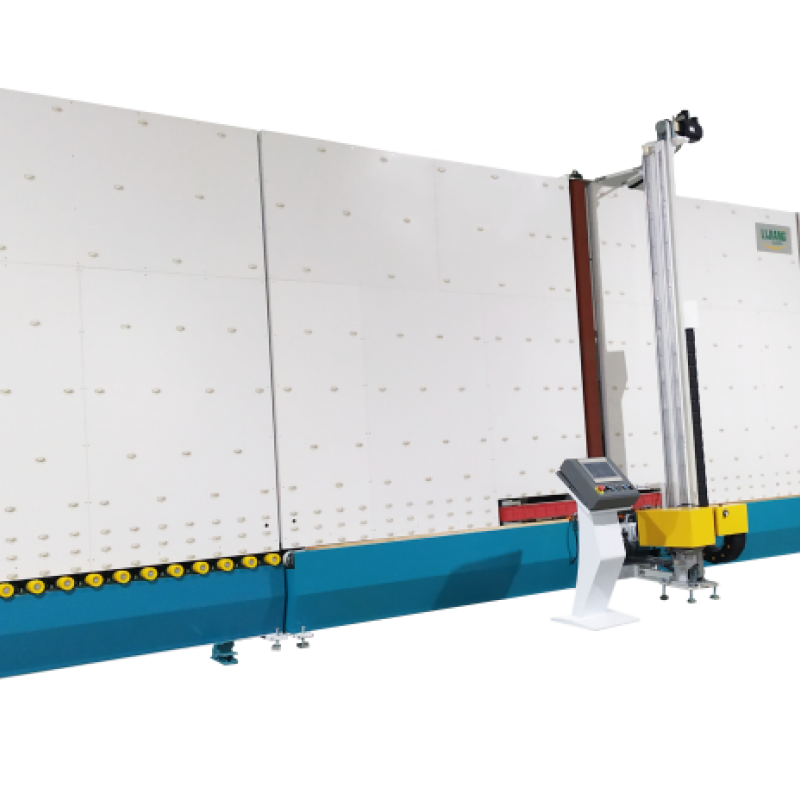

Cantilever crane LJXJ300LJ2520P(500KG) Vacuum glass lifterPneumatic glass handing manipulator is operated by using compressed air. The device does not use electricity and is safe and reliable, easy to operate. It is an essential glass handling tool for a modern glass processing industry. The air flowing through the vacuum generator causes Vacuum Pressure to suck the glass. A cylinder stroke is acted by receiving the command signal from the compressed air in an inlet pipe.

Contate agora

LJXJ300 glass handling lifting cantilever craneThe pneumatic glass handling manipulator is operated by compressed air. Glass sucker crane does not use electricity, safe and reliable, easy to operate. Glass crane is an indispensable tool for glass transport in modern glass processing industry. The air is passed through a vacuum generator to create vacuum pressure and suction glass. Cylinder travel is performed by receiving the command signal from the compressed air intake pipe.

Contate agora

Glass vacuum lifter Glass lifting machine is used to loading and unloading glass for making insulating glass. The glass crane is vertical with arm and column, located in the front or the ending of the IG line and sealing robot. Glass suction crane is one of the vacuum spreaders, which is mainly used in glass production and processing and glass installation on construction site. The best equipment for handling glass is used in glass production and processing, insulating glass, laminated glass, vertical production line and horizontal manual gluing line. It can be used fo

Contate agora

Could Automatically Flip and Suck Curtain Wall Glass Vacuum Glass Lifter for Insulating Glass ProcessProduct DescriptionLJXJ800 Glass Cantilever Crane Loading Lifter EquipmentA pneumatic glass handing manipulator is operated by using compressed air. The

device does not use electricity and is safe and reliable, and easy to

operate. It is an essential glass handling tool for the modern glass

processing industry. The air flowing through the vacuum generator causes

Vacuum Pressure to suck the glass.

Contate agora

A Cantilever Crane with a bridgelike spanning shape installed on high helps that pass along tracks on the ground. cantilever-kind gantry cranes are used to transfer bulk cargoes, which includes coal and ores, and piece cargoes, consisting of excessive-grade rolled metal.Technical dataMax loading260/500/800kgAir Control parts AIRTACSuction cups2-8pieces Cup MaterialsSiliconeSliding method ManualWeight400/450/480kgArm length4 metersRotation angle AIRTAC Rotate 90 ° Flip 90° Left and Right,Up and DownColumn height4 metersGas storage function

Contate agora

The type of LJCJ01 smart insulating glass gas filling machine is special equipment for inflatable hollow glass. The device uses microcomputers and imported sensor to form a closed loop control system, high degree of intelligent equipment, precise control, pneumatic adjustable concentration, high charging efficiency, the operation is simple.

Contate agora

Main featureIt is used for filling argon into insulating glassExcessive efficiently, allowed for 4 pieces of IGUWhen the gas is full,it will alarm and stop automaticallyTechnical dataPower supply220V 50HzTotal power0.1kwDimension620*439*700mm

Contate agora

Main featureClean working, easy and flexibleIt is used for fixing and rotating glass at the same time as manual coating the out of doors of ig glassThe center sucker is appropriate for small portions of glass,but,more manual frame is for huge quantities of glassTechnical dataPower supply380V 50HzTotal power0.37kwOperating dimension1500*1500mmDimension600*550*985mmWeight75/48kg

Contate agora

• Can efficiently seal the desiccant,to hold dry• Manual filling desiccant into spacer frame• Recyclable• Easy operating, easy and flexiblePower supply220V 50HzTotal power1kwDimension2490*400*2200mm

Contate agora

• Can effectively seal the desiccant,to keep dry• Manual filling desiccant into spacer frame• Recyclable• Easy operating, simple and flexiblePower supply220V 50HzTotal power1kwDimension2490*400*2200mm

Contate agora

Main featureIt is used for storing the gun when manual glue gun stop work during the process of gluing insulating glassStoring at low temperature,to prevent sealant solidifyApply to polysulfide and siliconeCan be effectively reduced waste when cleaning the glueTechnical dataMax refrigerating temperature70ºCMin heating temperature-40ºCTotal power3.8kwRefrigerating<150minOverall dimension1550*60*1300mm

Contate agora

PERFORMANCEAdopt the servo manipulate feeding tool, spacer frame duration can be adjusted with an accuracy of 0.1 mm/mCNC bending attitude manipulate tool with adjustable accuracy of 0.1°Set up four companies of spacers storage unitsAluminum bar with a couple of sizes can be determined on at willAutomatically regulate the bending speed regular with the size of the aluminum frame to avoid the deformation of the huge frame and make certain the immoderate speed and continuity of the small frameAutomatic non-forestall connection of spacer, decreasing spacer, avoidance of spacer bar jointNo materia

Contate agora

1. Vertical Edge Deleting Machine UsageVertical Edge Deleting Machine LJCM2545 is used to remove low-e film from edges of the glass. It can be connected to the insulating glass production line and is necessary equipment in insulated glass processing. Speed of transmission and grinding are adjustable, and the machine is equipped with automatic cleaning system.

Contate agora

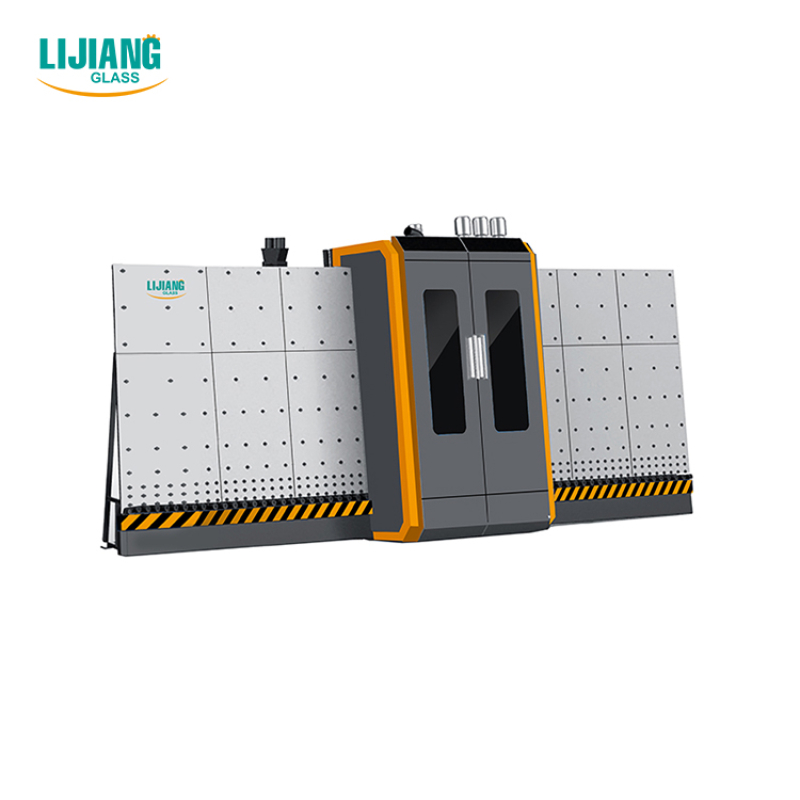

Vertical automatic insulating glass production line LJBZ2535Main characteristics of insulating glass production line:• Extra long insulating glass can be compressed twice• The insulating glass production line adopts servo torque pressing glass• The pressing plate adopts adjustable screws to ensure lasting pressing and high precision• With precise adjustable front platen mechanism• The system of insulating glass production line supports fault information diagnosis• The platen can be opened up to 400mm wide for easy maintenance• Automatic insulating glass production line is suitable for the prod

Contate agora

PERFORMANCEJapan yaskawa servo manipulate machine, whole computerized and high-efficiencyComputerized reminiscence function, no need to enter parameters time and againAutomatically restore glass corners with scraper and curlerGadget has 4 sections, can maintain glassRobotically diploma glass duration and glue depth, adjust sealing velocityAdopt timing belt, smooth transfer and accurate roleEvery vehicle-feature is with manual operationCan coat double glass, fashioned glass, step glass, triple glassOne set of booster pump controls organizations of sealantsAutomatic timing glue discharging

Contate agora

KTLQ-2500 Vertical Glass Washing MachineKTLQ-2500 glass washing machine can wash maax glass of 2500mm*3500mm, more large size and less size can be optional. - Self-Diagnosis system with touch screen on computer. - Stainless steel washer with 8 ( 6 ) brushes, soft brushes from MONFORTS of Germany, hard brushes automatically open when Low-E glass input. - Rotate speed of brush frequency control. (optional) - Stainless steel air knife is automatically adjustable according to glass thickness, Max thickness to 19mm.

Contate agora

Smart insulating glass gas filling machine is special equipment for inflatable hollow glass. The device uses microcomputers and imported sensor to form a closed loop control system, high degree of intelligent equipment, precise control, pneumatic adjustable concentration, high charging efficiency, the operation is simple.

Contate agora

Main feature Easy operating, simple and flexibleIt is used for fixing and rotating glass when manual coating the outside of IG glassThe middle sucker is suitable for small pieces of glass,however,extra support frame is for large pieces of glassTechnical dataPower supply380V 50HzTotal power0.37kwOperating dimension1500*1500mmDimension600*550*985mmWeight75/48kg

Contate agora

Designed for used with a crane or other hoisting equipment, the RSY-600-6 lifters employ vacuum to hold a load for lifting, and they provide manual 360°rotation and mechanically assisted, manual 90°tilt movements for load manipulation. Length Maximum 2596mmMinimum 997mmWidth Maximum 1868mmMinimum 821mmPer-Pad 184lbs[100KG]Maximum [800Kg][140KG ]12Volts DC, 10Amps7 amp-hoursStep 1: Use the glass lifter sucker slowly close to the glass, and then the main power switch (⑦) ON, the vacuum pump switch (⑧) ON.

Contate agora

PERFORMANCEJapan yaskawa servo control gadget, complete computerized and excessive-efficiencyAutomated reminiscence function, no want to enter parameters again and againRobotically restore glass corners with scraper and rollerMachine has four sections, can save glassAutomatically measure glass size and glue depth, adjust sealing speedAdopt timing belt, smooth transfer and accurate positionEvery auto-function is with manual operationCan coat double glass, shaped glass, step glass, triple glassOne set of booster pump controls two groups of sealantsAutomatic timing glue discharging functionThe gl

Contate agora

Smart Vertical Edge Deleting Machine LJCM2545 Main feature• Two-way glass access• Delete double and triple silver low-e glass• Automatically measure glass size• Automatically distinguish low-e surface• Edge deletion is adjustable• The head can be rotated 360°• Safe and full automatic device• PLC control system, touch screen interface • Six servos control system• Intelligent control system, can recognize batch processing Technical dataMax. glass processing size2500*4500mm Min. glass pr

Contate agora

PERFORMANCEAdopt the servo manage feeding gadget, spacer body length may be adjusted with an accuracy of 0.1 mm/mCNC bending attitude manage gadget with adjustable accuracy of 0.1°Set up 4 businesses of spacers garage unitsAluminum bar with more than one sizes may be decided on at willAutomatically alter the bending velocity consistent with the scale of the aluminum body to keep away from the deformation of the huge body and make sure the excessive velocity and continuity of the small bodyAutomatic continuous connection of spacer, cutting spacer, avoidance of spacer bar jointNo material prompt

Contate agora